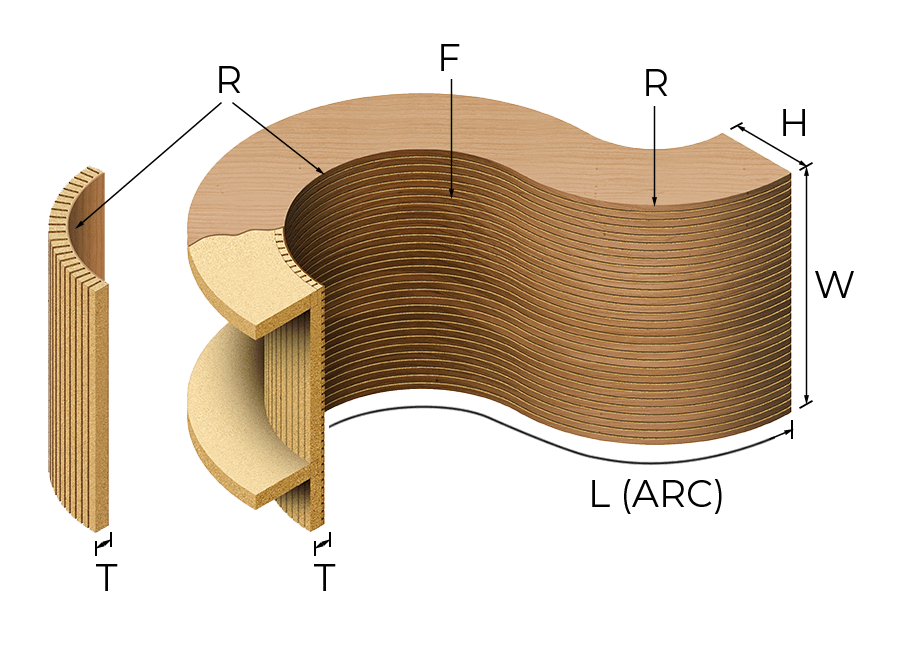

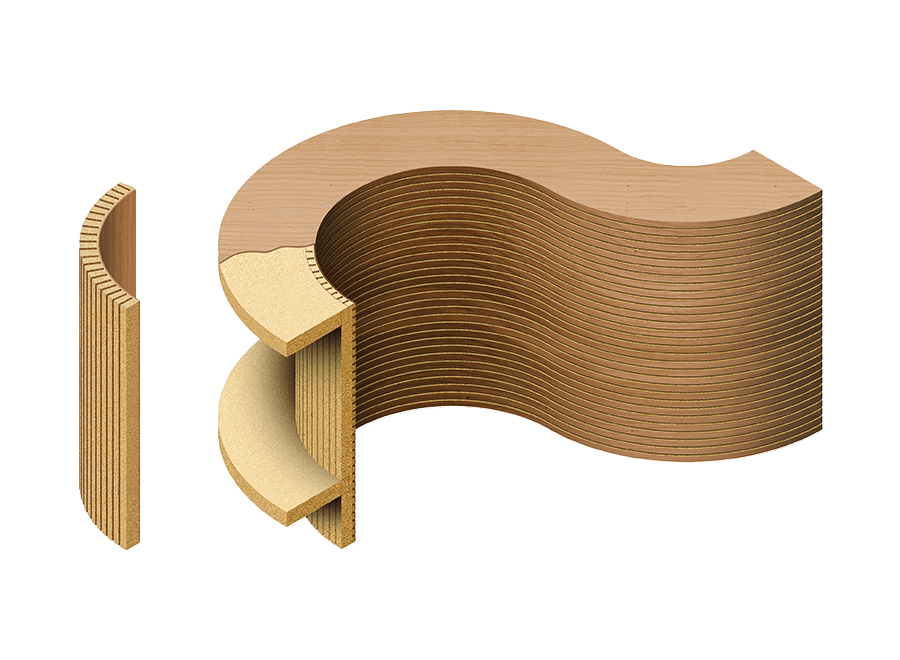

Custom-curved acoustic panels shaped to meet the design aesthetic of any space and machined to allow for maximum sound control and design customization. Available in every Aluratone pattern.

| SYSTEM | FLEXIBLE | RIGID |

| R (MIN RADIUS) | 120” | 18” |

| H (RETURN HEIGHT)1 | 3/4” | 3" |

| T (FACE THICKNESS) | 3/4" | |

| W (MAX WIDTH) | 48" | |

| L (MAX ARC LENGTH)2 | 120" | |

| F (FACE PATTERN) | A700,A7X03,A900,A9X0 | |

1Height - Custom return heights available for >3”

2Length - Length of the arc, not overall panel length

3Pattern - A7X0 only available at 120”+ radius

This new city hall building includes a new 500-seat council chamber. The architects designed a state-of- the-art chamber with an extreme contemporary design within. The first thing that catches your eye upon entering is the unique free flowing ribbons of wood surrounding the entire interior walls. The chamber space required a great degree of acoustic control. The designers were able to accomplish this while adding a very contemporary design feature… custom shaped acoustical wood walls.

Discover 2024's

Revolutionary

Design Trends

FREE DOWNLOAD

Get Innovative Ideas for Your Next Project

Enter your email below and we’ll send you some great inspiration!

Title

Architect Name:

Location of Project:

Product Name:

Notes/Credit:

Case Study: