One of the most critical relationships in any wood industry is that of wood and moisture – specifically, the fragile balance of moisture content and relative humidity that helps wood to maintain its shape. Wood is hygroscopic – “hygro” meaning related to water, not “hydro” meaning literally water – which means it will absorb and desorb moisture from the surrounding air. This equalization is a safe, natural process as wood is a natural product, but it can also be problematic – mostly in situations where wood is used as a finished product and high or low moisture of the surrounding air is of concern.

The Drying Process

When a tree is felled, the lumber that is produced from it is considered “green”, or containing a large amount of moisture. This moisture is found in two states: free water, which is water that sits in the pores of the wood, and bound water, or water that is held within the cells of the wood. When exposed to air, free water will naturally evaporate, drain, or otherwise be shed until the lumber reaches the Fiber Saturation Point (FSP), or the point at which only bound water remains. While at this point the lumber is no longer considered “green”, it is not yet dry as the bound water remains.

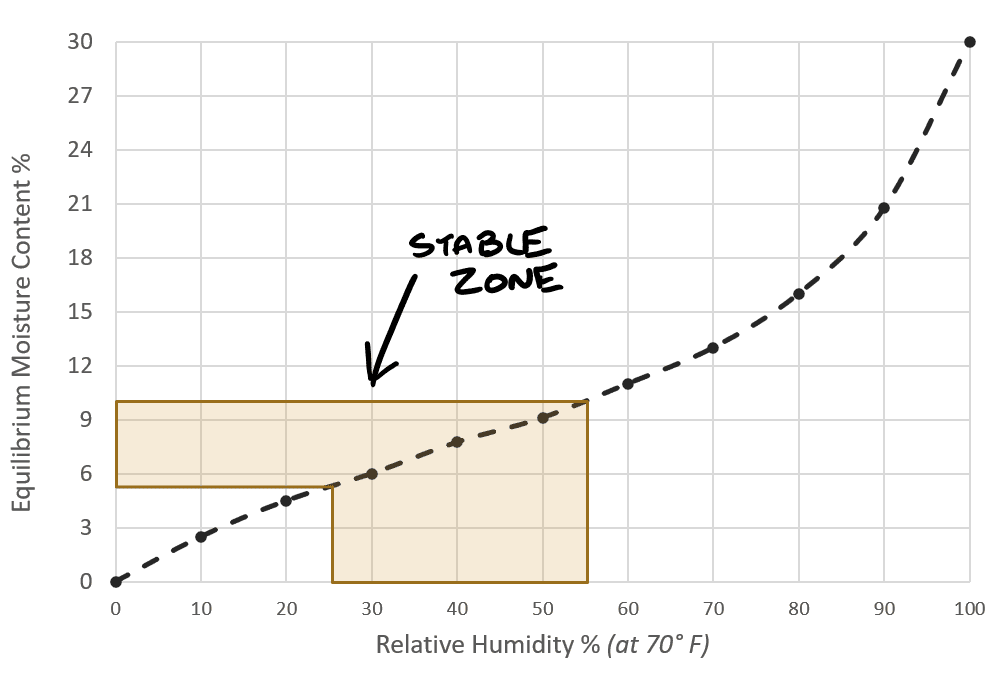

Wood, before use in cabinetry or carpentry, must be kiln-dried, removing the bound water from the cells and bringing it to a stable state. In this state, the lumber has reached Equilibrium Moisture Content (EMC). In theory, if lumber has been dried to EMC, the moisture that remains in the wood after the drying process will be relative to that of the air it is in contact with (i.e. as the relative humidity rises, so does the EMC and vice versa). The Architectural Woodwork Institute (AWI) has published standards for drying lumber, indicating that hardwood must be dried to 6-9% moisture content while softwoods must be dried to 10-12% moisture content. The suggested “Optimum Climate Controlled Relative Humidity” of the installed space is 25-55% relative humidity for most of the U.S. and Canada and correlates directly to the dried moisture content of lumber, creating a “stable zone”, where wood movement from shrink/swell is limited. The purpose of this standard is to prevent as much movement and dimensional change in lumber as possible after it has been installed as a finished product.

Expansion and Contraction of Wood

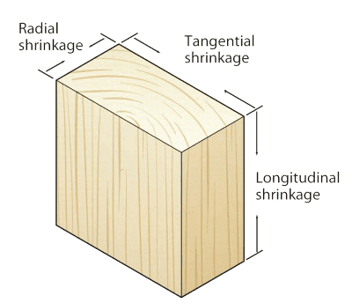

In reality, humidity changes constantly. It can be measured and it can be sensed by smell, touch, or even sound. As the relative humidity lowers, wood products dry out, the moisture in the wood changes, and the material begins to shrink. The opposite happens when humidity rises. Wood, organic in nature and always cut out of different sections of a log with growth ring orientation varying, does not shrink and swell uniformly. In Wood Science, this is called the T/R Ratio. T – or Tangential – refers to the shrink or swell of wood parallel to the growth rings (6%-10%, on average) while R – or Radial – refers to the shrink or swell of wood perpendicular to the growth rings (3%-5%, on average). The larger disparity between these two numbers results in more cupping, warping, twisting, etc.

The good news is there are ways to combat the dimensional change of finished wood products through humidity control practices, specific wood sawing techniques, and species selection.

First, humidity control practices are fairly self-explanatory, but the addition of humidifiers and dehumidifiers to maintain humidity within the specified range will limit shrink or swell, which results in less warping and less dimensional change.

Second, selecting wood sawings with T/R ratios closer to 1.0 will result in uniform expansion and contraction. Quartersawn and Riftsawn are the two most common cuts selected to achieve a near-1.0 ratio as their orientation within the log promotes equal expansion in all directions.

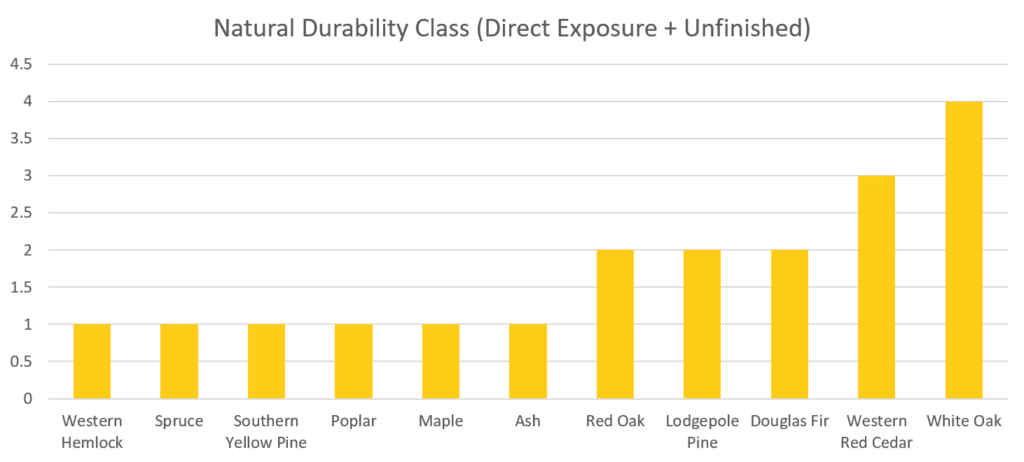

Third, some species are more water-resistant than others and therefore more resilient to change or damage due to moisture. White Oak, for instance, is an almost ubiquitous choice for Wine and Whiskey barrels as the vessels of the wood contain tyloses, a balloon-like plug that fills the pores and prevents water passage. Some exotic species such as Teak and Ipe secrete oils that naturally wick moisture. An Oregon State University study titled “Natural Durability Of Wood: A Worldwide Checklist Of Species” provides an excellent foundation upon which to make decisions regarding the selection of species.

Regardless of what you’re working on, you can be confident that if you’re working with Rulon International, we’ll evaluate the conditions the final product will be installed in and provide an assessment of species that can meet the needs of your project.

To find out more about cuts and grains, schedule a design call with our team today