Children's Healthcare of Atlanta

THE CHALLENGE

Children’s Healthcare of Atlanta’s North Druid Hills campus is the astonishing vision of pediatric care that aims to directly connect medical research with children in need all while maintaining an environment that is both healthy in design and transformative in spirit. Located inside the beltway off of I-85 just nine miles northeast of downtown Atlanta, the campus consists of the Arthur M. Blank Hospital, Center for Advanced Pediatrics, an outpatient clinic, and a Support Center along with 20+ acres of outdoor greenspace.

The first on-campus building to open was the Center for Advanced Pediatrics in 2018, an impressive 8-story, 260,000 sqft outpatient care center that provides 40+ services to medically complex patients with chronic illnesses. The calming lobby space is the centerpiece of this building where a combination of Curvalon and Flat Veneer Panels climb the walls and spread out across the ceiling, mirroring the outdoor tree canopies and paying homage to Atlanta’s affectionate tag of being the “city in a forest”.

"Understanding the curvature of the transition panels on this project proved to be an immense challenge. Each individual panel had to be 'unfolded' like a sheet metal component, translated onto a veneered wood panel, and kerfed to allow it to bend to match the radius shown. Our engineering team went above and beyond."

- Aaron Journot, Rulon International

THE ACTION

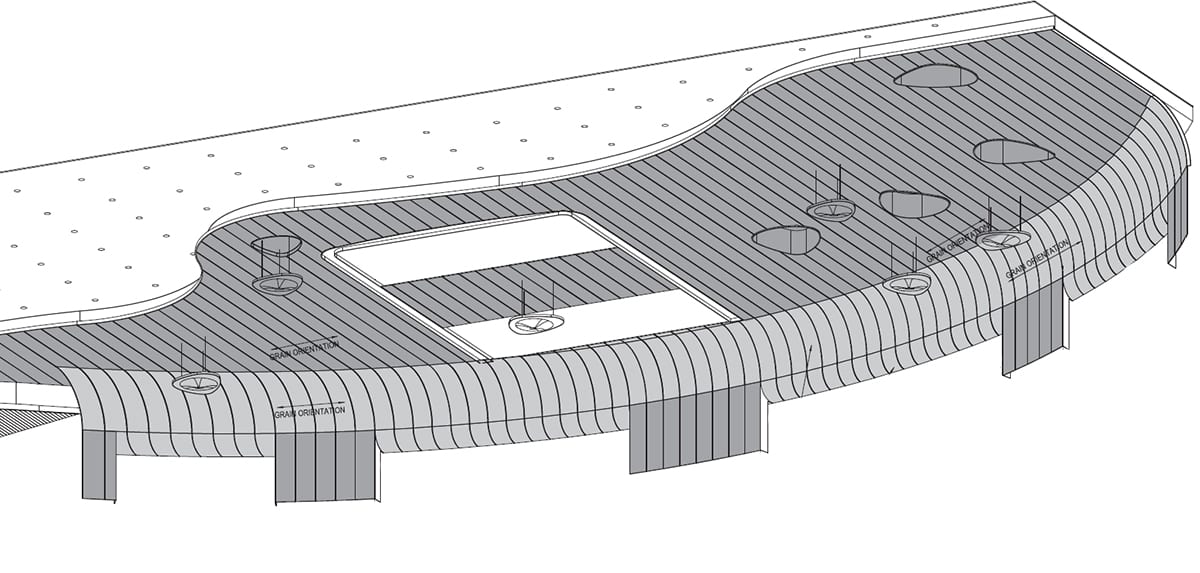

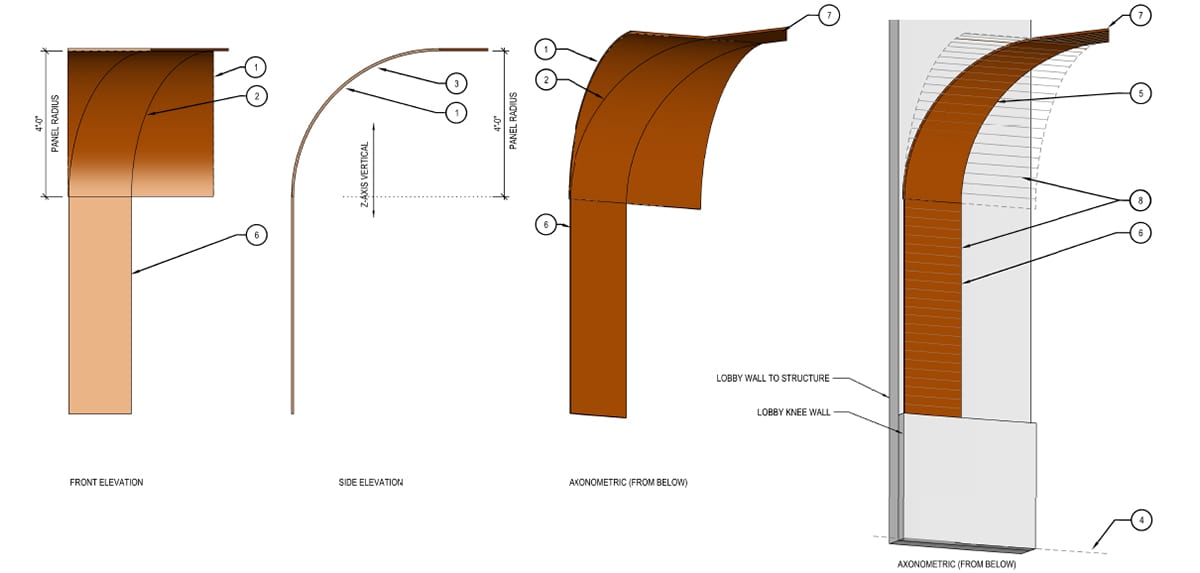

The design of the ceiling is one of the most conceptually difficult projects Rulon has ever worked on. In this half-circle entry space, Flat Veneer Panels line the ceiling and the walls in 2’-0” wide strips while complex Curvalon panels create the arcs that allow the wood to curve from floor to ceiling. The wall panels at the center of the room arc mirror the size, orientation, and reveal spacing of the ceiling panels, but as you move away from the center, this symmetry moves further and further apart. In addition to alignment, the transition panels are curved and need to be cut to be parallel to connecting floor and ceiling panels and kerfed (i.e. machined to allow for panel flex) at the correct angle to maintain an exact radius and proper alignment as required by the room design.

From a manufacturing standpoint, the conceptualization of skewed, radial panels was difficult enough but designing them, laying them out in 3D optimization software, and cutting them to the correct shape proved even more mind-bending. The key hurdle was unfolding the surface curvature of panels to the far right and left of the center radial line as this resulted in panels that were too large for nominally-sized MDF sheets. The curved panels that fell within the first 20 degrees left and right of the center radial line could be cut from 4'-0" x 8'-0" sheets. However, the panels to the far right and left of the center radial line exceeded nominal substrate dimensions for panel manufacturers, some measuring in as much as 5'-0" wide and 11'-0" long. In order to solve this problem, extra reveals were added to limit overall panel size and provide better panel optimization. Rulon implemented a 3D model of the lobby space to ensure panel location, layout accuracy, and panel edge orientation.

In order to prepare for potential challenges in the field, as well as become familiar with the ceiling installation - the installers joined the Rulon International engineering team at headquarters to build a mock ceiling and wall section. After working out complications in the various planes, the installation process was completed smoothly resulting in an incredible finished product.