Marcus Nanotechnology Research Center

THE CHALLENGE

Part of Georgia Institute of Technology’s campus in Atlanta, Georgia, the Marcus Nanotechnology Research Center building brings together leading researchers in fields from nano technology to biotechnology. As part of the new additions to the campus, the center supports one of the largest cleanroom facilities in the southeast United States for organic and inorganic research.

The design of the building demonstrates aggressive forward thinking from inception to completion to meet LEED certification requirements. While the majority of the 190,000 square foot building is designed to feel light and airy, complementing the cleanroom space, the main corridor employs Rulon International’s Accent Beam ceiling and wall system to create a harsh juxtaposition.

Today, potential recruits enter the space and quickly realize that the success of their future resides within this cutting edge facility and university.

THE ACTION

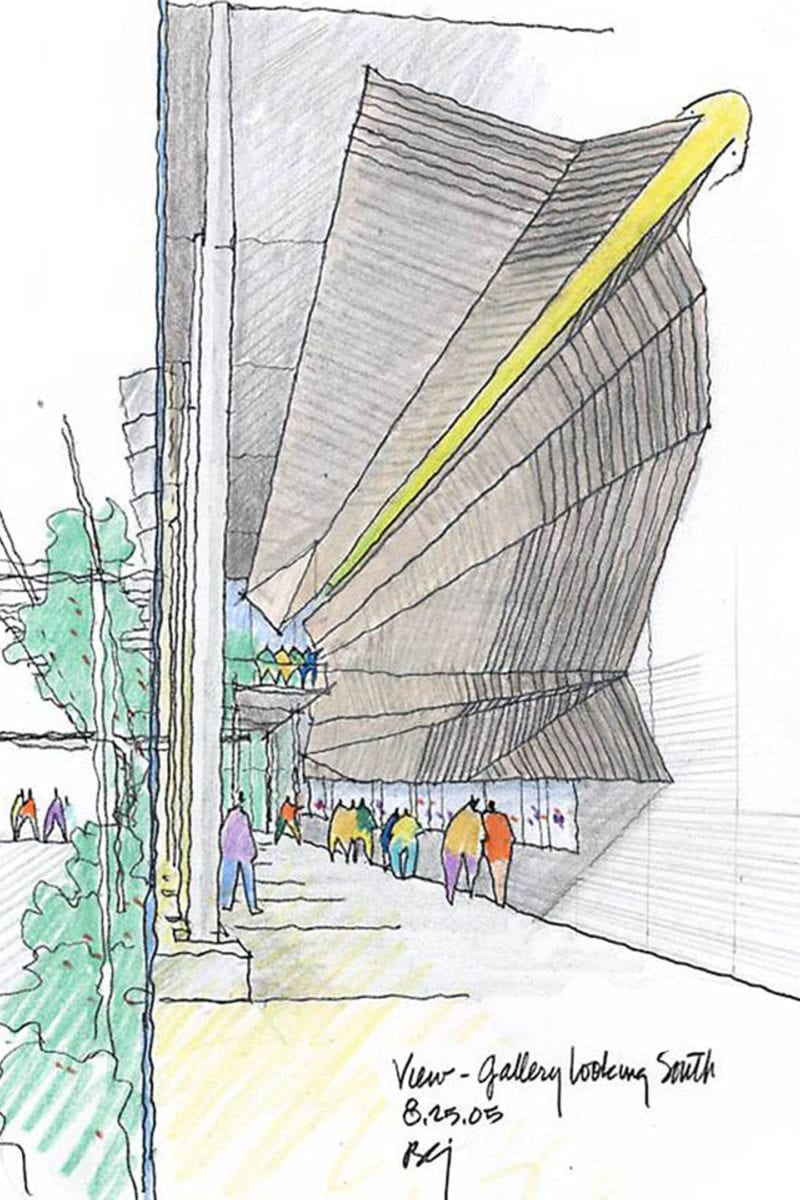

This one of a kind design stems from the desire to emulate the metaphoric feeling of nanoparticles floating through a biomechanical system and forcing patrons to feel the same. Rulon International set the stage for an uncharacteristic Accent Beam design beginning with the Architects’ sketches and preliminary details.

To achieve the design intent - a look similar to baffles - while also accommodating the large profile design, Rulon International’s engineering team proposed the solution of attaching three 2 x 6 x 2 single-part, decorative beams, in combination with a 2” reveal, to a 24” panel. To create the different delineations, the panel sizes ranged from 8’ to 14’ meeting an integrated light bar at the peak.

3D CAD drawings played a vital role in the bidding process, submittal process, onsite meetings, and installation. The complex geometry of the panel contours required Rulon International’s engineering team to develop a solution by which the installing contractor could attach panels top down utilizing a system of simultaneous saws set at opposing angles to simplify field cutting.