Seminole Hard Rock Hollywood

THE CHALLENGE

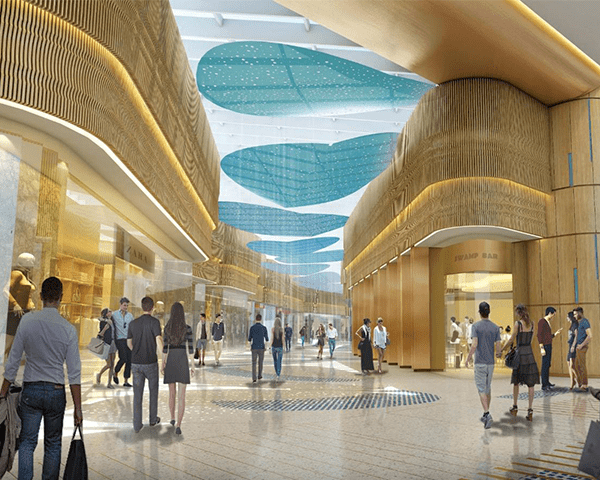

This casino’s new, nearly $1.5 billion expansion is anything but ordinary; adding 200 table games and over 3,000 slot machines, the public spaces are a playground for anyone looking to spend - or win - money. True to the theme of the hotel and casino, the elegant yet refined shopping corridor incorporates cloud-like ambient lighting and curved, multi-tier wooden grilles evoking the imagery of organic sound waves.

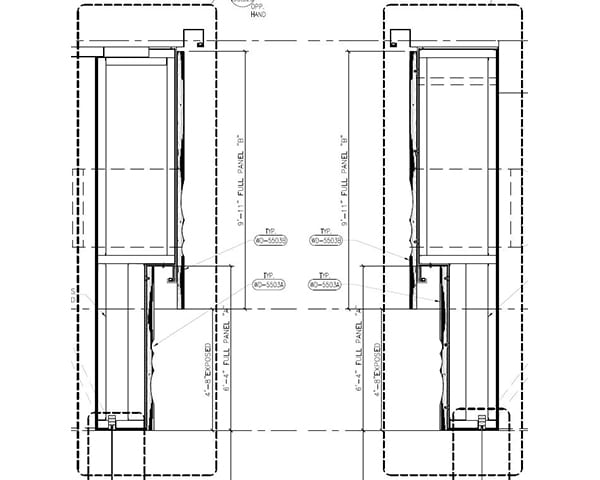

The original design for the wooden grille wall system included two offset layers designed to follow the curvature of the room while maintaining vertically- aligned, solid White Oak wooden blades. Varying arc lengths for each of these offset layers presented a serious challenge to the manufacturer - devise a constructible, budget-conscious system without compromising design intent.

"Rulon overcame the design and coordination challenges by working closely with the project design team, the Rulon manufacturing team, and installing contractor to provide a complete system sequentially packed for ease of installation."

- Tom Anderson, Rulon International Engineering Manager

THE ACTION

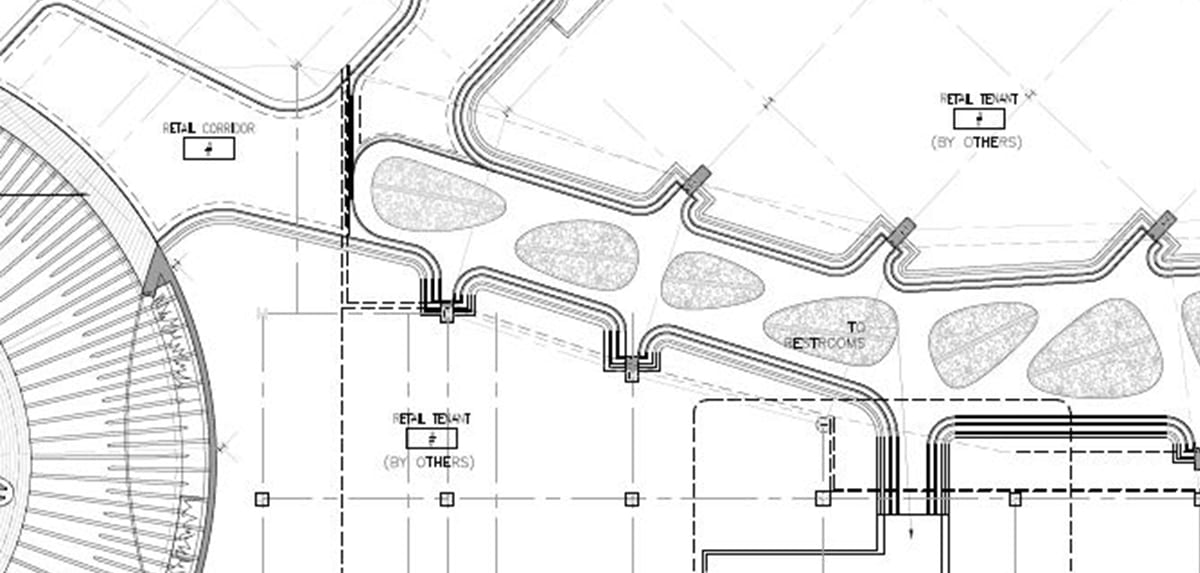

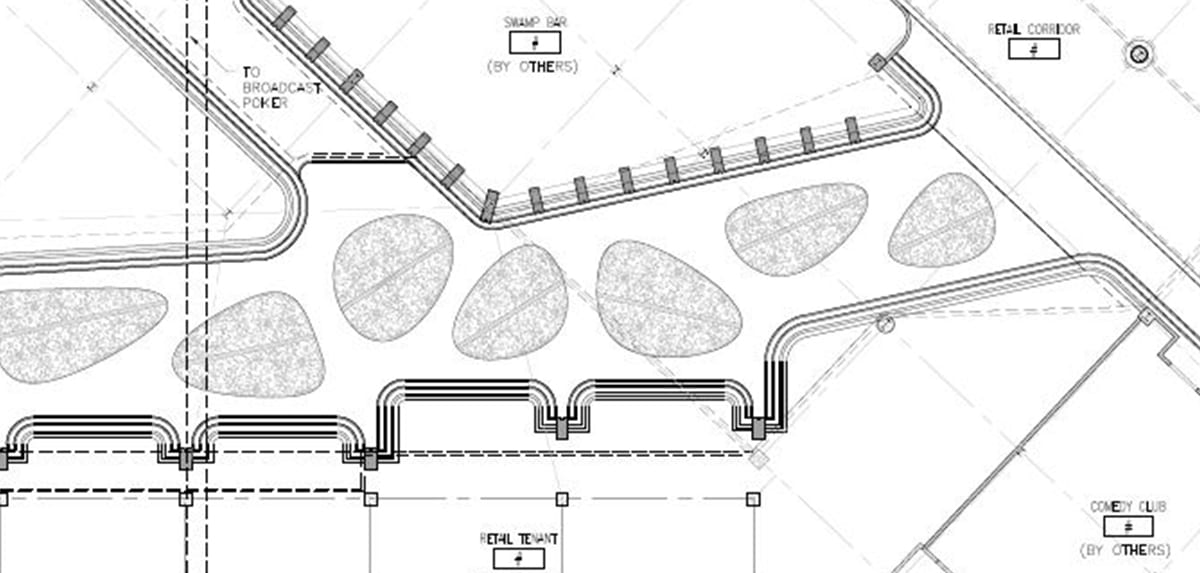

Following extensive feasibility evaluations with Rulon International, the panel grille system was redesigned to maintain consistent spacing between vertical blades, planned out to incorporate a set of interchangeable modules, and manufactured as a veneered system to achieve the highest level of consistency. In addition to the coordination between layers, adjacent panels also required consideration as the face of each vertical blade was machined to a specific profile that, when placed next to consecutive modules, created the visual of sound waves moving throughout the space.

Upper-tier panels were manufactured at 10 feet tall and extend proud of the lower tier portion of the wall system at only 8 feet tall. An inverted light cove was included between the systems to create a visual break and provide ambient light for the occupied space. In total, the 15,000 square foot system consists of 40 unique modules (including 20 left-hand and 20 right-hand modules for opposing walls) that were designed by Rulon International to simplify both the layout and the installation process.

Site meetings were conducted to evaluate material staging, review crating and labeling strategies, and work through MEP coordination details. The ceiling contractor made quick work of the installation process, instituting a two-crew, two-tier, rolling tower scaffolding system, which, in combination with the consecutive-panel packaging and labeling system, resulted in a quicker than expected completion. Due to the high level of coordination and early design involvement with Rulon International, this project was successfully completed on time.