This new city hall building includes a new 500-seat council chamber. The architects designed a

state-of- the-art chamber with an extreme contemporary design within. The first thing that catches your eye upon entering is the unique free flowing ribbons of wood surrounding the entire interior walls.

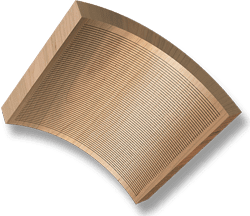

The chamber space required a great degree of acoustic control. The designers were able to accomplish this while adding a very contemporary design feature… custom shaped acoustical wood walls. The panels are 38 inch high acoustical wood veneered panels that have individually designed, undulating or serpentine shapes of varying sizes. The walls have 6 rows of “radiused acoustical panels. The frequency of the “waves” alternate between each row. The wood panels were made using Beech veneer with a clear finish.

To say this was a very complicated project is an understatement. The planning stage alone required a great deal of time. In order for the installers to work with such a complex product, visits to the manufacturer were required to review panel sizes, finishes and framing. Installation process was also reviewed. Mock up panels were made so the installers could gain a full understanding of the panel nuances and intricacies.

To say this was a very complicated project is an understatement. The planning stage alone required a great deal of time. In order for the installers to work with such a complex product, visits to the manufacturer were required to review panel sizes, finishes and framing. Installation process was also reviewed. Mock up panels were made so the installers could gain a full understanding of the panel nuances and intricacies.

With all the pre-planning, careful double checking of all measurements, and close coordination between manufacturer and installers, this complex project was done problem free and on time.

The success of this project totally depended on a flawless installation. The installers had to deal with a room geometry that added to the job complexity.

The rear wall is radiused with the side walls angled in towards the front of the chamber. The curved geometry of the rear wall panels needed to be altered to create the same look as the side walls. The side walls followed the sloping floor from the back wall to the front of the chamber. The radiused panels were made very custom to not only have the serpentine shape per panel but also to follow the curve of the back wall. The back wall panels had to transition smoothly around the corners to the side walls. The very complex installation was made easier by incorporating horizontal sill plates for panel support and alignment and metal ‘Z’ clips for securing the panels to the wall framing. The curved panels at the front of the chamber were required to be acoustically reflective. The rear panels were required to be acoustically absorptive. This was achieved working closely with the manufacturer and the acoustician.