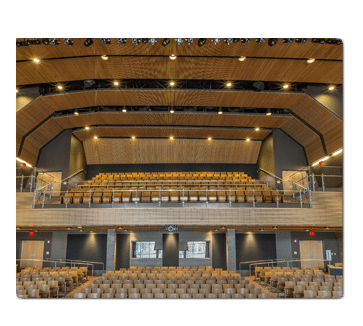

Legacy Emmanuel Children's Hospital

This project was a hospital that needed a new building dedicated entirely to the care of children. The design aspect of the interior features elements that cater to the mind of a child but also has the class and sophistication to appeal to adults as well. Upon entering the hospital one is greeted by a fantastic wood panel grille ceiling. This ceiling seems to make its way down a wall and continue down a hallway.

In addition, the main ceiling has layers of gull-wing panel grille sections that overlap other panel grille sections. Where the ceiling meets the wall the panel grille actually curves at the corner and then continues down the wall at an angle. This wall panel then curves to the lower connecting ceiling of a hallway. The panels continue down the hallway with undulations following the length of the corridor. The waves of the panel curves in the hallway ceiling were designed to match the curves of the hallway walls.

This project has the appearance of complexity but actually was relatively easy to install. This was due to the installer taking a lot of necessary time, (2 months), properly coordinating or pre-planning in the design phase with the ceiling manufacturer. The main technology that facilitated the pre-planning and installation was 3D modeling. A great deal of 3D modeling was required to ensure every custom panel fit in place. All of the panels had to be numbered and installed in very specific sequence. All of the curves and angles of the panels were facilitated by the use of pre-shaped suspension grid. The installers built a separate custom frame to support and mount the vertical panel grille wall section. The manufacturer provided the radiused grid, which was suspended using 15/16 heavy duty wire. All of the panel grille sections had matching return edges. The return edges were factory cut by the manufacturer to perfectly match the radius of the panel grille.

This project has the appearance of complexity but actually was relatively easy to install. This was due to the installer taking a lot of necessary time, (2 months), properly coordinating or pre-planning in the design phase with the ceiling manufacturer. The main technology that facilitated the pre-planning and installation was 3D modeling. A great deal of 3D modeling was required to ensure every custom panel fit in place. All of the panels had to be numbered and installed in very specific sequence. All of the curves and angles of the panels were facilitated by the use of pre-shaped suspension grid. The installers built a separate custom frame to support and mount the vertical panel grille wall section. The manufacturer provided the radiused grid, which was suspended using 15/16 heavy duty wire. All of the panel grille sections had matching return edges. The return edges were factory cut by the manufacturer to perfectly match the radius of the panel grille.

This LEED Gold certified project was successfully done from start to finish by the wise preplanning of the installer and the high end nature of the wood ceiling and the creative mind of the designer.

The wood panel grilles, all Poplar with a custom stain, required virtually no field cutting as all the pre-planning resulted in perfectly sized panels. The panels are 11 feet wide, one foot wider than industry standard.

The hallway panels had a radiused design with no reveals following the entire length of the hallway. Much of the potentially challenging issues were identified early on and made simplistic. The installation was progressive and required coordination between the trades. Electricians had to work closely with the installers as the lighting was integrated with the ceiling. Scaffolding was needed for the high ceiling in the atrium area while a lift was used for the panels in the hallway.